The Influence of Strenuous Welding Examination on Market Requirements: Promoting Safety And Security, Reliability, and Conformity Across Numerous Industries

The duty of extensive welding examination is increasingly identified as a vital element in boosting industry standards, where security, integrity, and compliance take precedence across diverse markets. By making certain conformity to established guidelines, such as those stated by AWS and ISO, these assessments not just alleviate dangers yet also cultivate a sense of accountability among professionals. As markets develop and deal with new challenges, the effects of these techniques might prolong beyond mere compliance. What transformations might we anticipate in welding methodologies as the demand for top quality and safety and security heightens?

Importance of Welding Assessments

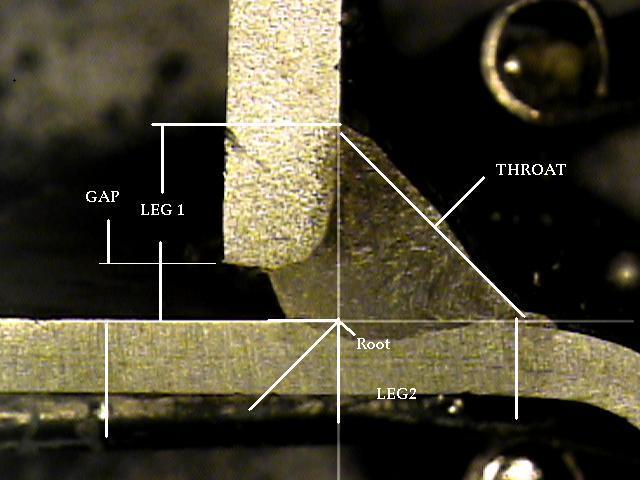

Recognizing the critical duty of welding evaluations in keeping high quality and safety criteria, market specialists prioritize these evaluations to make certain architectural integrity. Welding assessments serve as a vital checkpoint in the fabrication procedure, identifying flaws that could jeopardize the longevity and safety of bonded frameworks. By systematically evaluating welds, assessors can detect problems such as insufficient infiltration, porosity, and cracks, which might not show up to the naked eye.

The significance of these examinations extends beyond simple conformity; they are necessary for guarding lives and shielding investments. In vital sectors such as building, production, and aerospace, a single defective weld can result in disastrous failings, leading to both economic loss and human casualties. Consequently, applying rigorous inspection protocols mitigates these risks and enhances total task integrity.

Additionally, constant welding examinations cultivate a culture of top quality across organizations, encouraging welders to abide by ideal methods and preserve high standards in their job. This commitment to high quality not just improves functional effectiveness but additionally enhances the credibility of companies within their respective fields. Hence, welding inspections are indispensable in advertising safety, integrity, and compliance throughout different sectors.

Secret Sector Criteria and Rules

The structure of welding inspections is underpinned by a robust collection of sector standards and guidelines that govern methods throughout various industries. Trick institutions, such as the American Welding Society (AWS) and the International Company for Standardization (ISO), develop guidelines that guarantee top quality and safety in welding operations. AWS D1.1 describes essential demands for welding steel frameworks, while ISO 3834 defines quality needs for fusion welding.

Along with these particular requirements, market policies like the American National Criteria Institute (ANSI) and Occupational Security and Wellness Management (OSHA) requireds additionally boost conformity by establishing security procedures and operational best practices. These regulations are critical in sectors such as aerospace, production, and building, where welding honesty is extremely important.

In addition, sector-specific criteria, such as those from the American Society of Mechanical Engineers (ASME) for stress vessels, supply additional layers of analysis to make sure that welds meet strict safety and efficiency requirements. Adherence to these requirements not only facilitates governing compliance but likewise fosters a society of high quality and integrity across the welding market, ultimately guarding public welfare and enhancing functional efficiency.

Benefits of Conformity and Integrity

Regularly adhering to sector standards and laws in welding assessments yields considerable benefits, boosting overall dependability and efficiency. The primary benefit is the assurance of top quality in welded joints, which straight contributes to the safety and security of structures and tools. Compliance with recognized criteria reduces the risk of failure and catastrophic occurrences, thereby securing both human life and valuable possessions.

Moreover, organizations that focus on strenuous welding inspections promote a society of accountability and expertise. This commitment not only boosts the reputation of the company however additionally instills confidence in stakeholders and customers pertaining to the integrity of product or services. Trusted welding processes result in decreased prices associated with rework, repair services, and possible lawful responsibilities stemming from substandard craftsmanship.

Furthermore, preserving conformity with sector criteria promotes smoother governing communications, as companies can conveniently show adherence to needed methods (Welding Inspection Gilbert Arizona). This aggressive technique can cause useful collaborations and chances within the market, in addition to access to new markets

Challenges in Welding Inspection

Navigating the intricacies of welding assessment presents a myriad of difficulties that can prevent compliance with sector requirements. The lack of standardized training for inspectors can result in different interpretations of assessment criteria, which might compromise security and reliability.

An additional challenge depends on the accessibility of innovative examination tools - Welding Inspection Gilbert Arizona. While innovations such as ultrasonic testing and radiography can improve discovery abilities, their use this link execution may be limited by expense or availability, especially in smaller sized operations. This variation can bring about a reliance on much less reliable evaluation techniques, raising the danger of undiscovered flaws

Furthermore, the busy nature of modern-day manufacturing typically pressures examiners to focus on rate over thoroughness, possibly forgeting crucial flaws. Last but not least, regulatory compliance can be intimidating because of the advancing nature of industry standards, leaving organizations having a hard time to stay up to date with the most recent needs. These obstacles demand continuous improvement in evaluation methods to make sure the stability of welded structures across various industries.

Future Trends in Welding Practices

Emerging technologies and evolving approaches are set to transform welding practices in the coming years. Innovations in automation, such as robotic welding systems, are acquiring traction, boosting accuracy and effectiveness while reducing human error. These systems will certainly not just accelerate production but additionally promote regular top quality control, resolving a few of the difficulties dealt with in manual welding.

Furthermore, the integration of man-made knowledge (AI) and maker learning into welding procedures is positioned to transform examination and tracking. Real-time data analytics will certainly allow predictive upkeep, permitting proactive treatments that decrease downtime and rise security. Boosted truth (AR) and digital reality (VIRTUAL REALITY) technologies are ending up being important in training welders, providing immersive experiences that improve ability development without the threats associated with standard approaches.

Sustainability is additionally a vital fad, as sectors seek greener methods. The fostering of environment-friendly products and methods, together with energy-efficient equipment, will likely come to be conventional. As sectors adapt to these adjustments, the focus will shift toward higher conformity with safety and security and ecological laws, ensuring that welding practices not only meet existing standards but try this out likewise lead the way for a more secure and more sustainable future.

Conclusion

To conclude, rigorous welding examinations significantly enhance industry standards by making sure safety, integrity, and compliance across numerous fields. By methodically recognizing issues and sticking to developed standards, these examinations mitigate threats linked with architectural failings. The promo of responsibility among welders causes greater high quality outcomes, fostering trust within communities. As industries remain to prioritize functional stability, the significance of complete examinations will just raise, ultimately benefiting businesses and society at huge.

The function of extensive welding evaluation is increasingly identified as a crucial element in enhancing sector standards, where safety and security, dependability, and conformity take precedence across varied sectors. Therefore, welding inspections are important in advertising safety, dependability, and conformity throughout various markets.

Secret institutions, such as the American Welding Society (AWS) and the International Company for Standardization (ISO), develop standards that guarantee high quality and safety and security in welding operations. AWS D1.1 describes important demands for welding steel frameworks, while ISO 3834 defines top quality requirements a fantastic read for fusion welding.

In final thought, extensive welding examinations considerably improve market requirements by making certain safety, reliability, and compliance across various markets.